The next generation for innovative coil processing.

The next generation for innovative coil processing

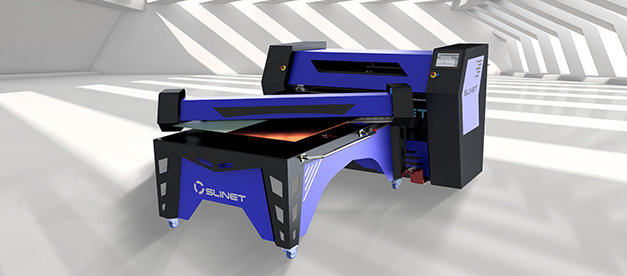

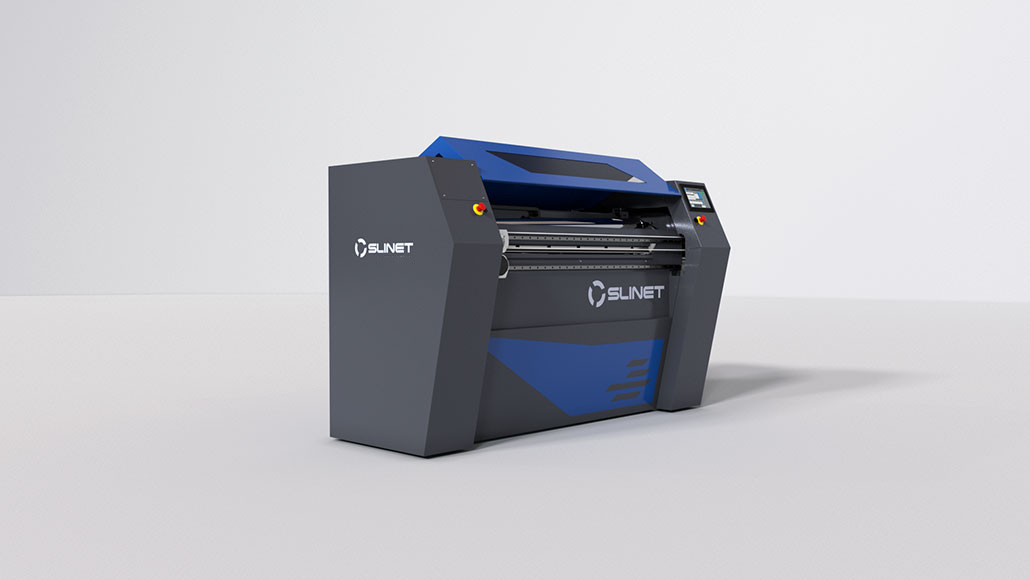

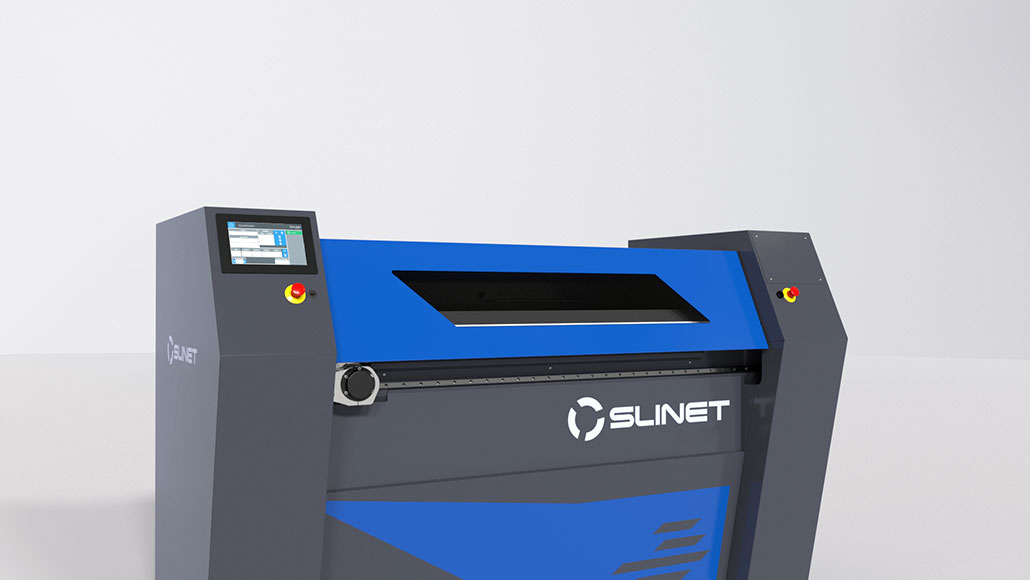

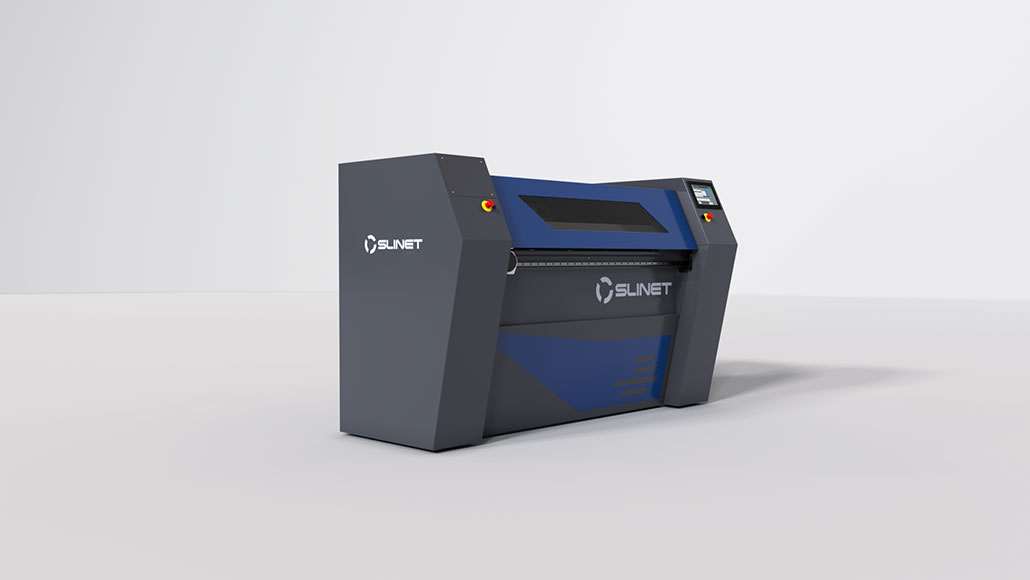

Slinet S 1.0

Markets are subject to permanent change.

In sheet metal forming, this also leads to an ever higher complexity of products and processes. The efficient production of blanks for profiles and flashings requires effective, high flexible and user friendly solutions.

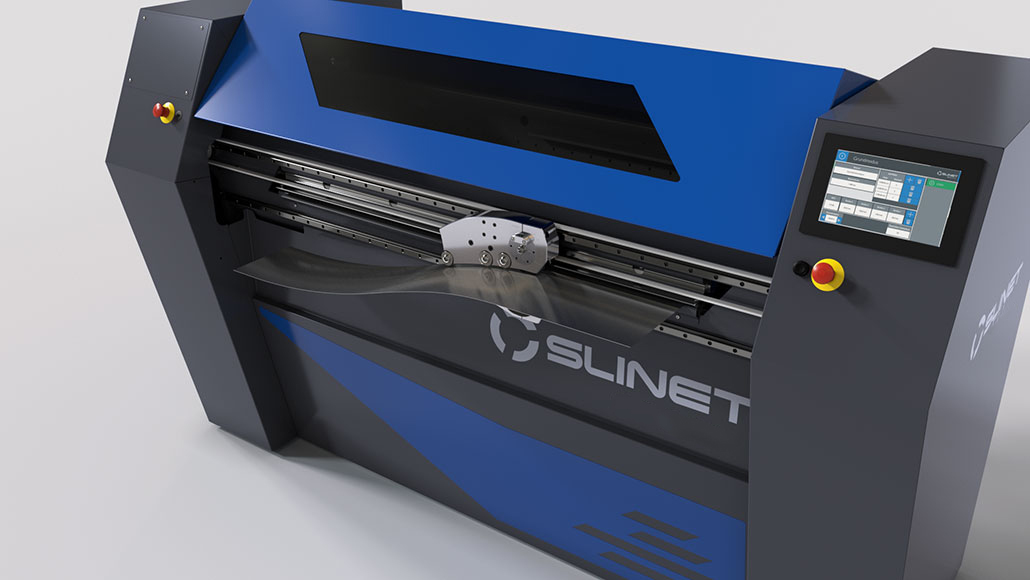

Slinet combines best quality with easy use with highest flexibility and automation.

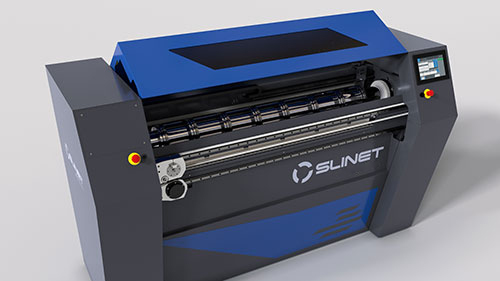

The cut to length unit SLINET S 1.0 allows precise cuttings with lowest set up time. With its full automated up to 8 knife setting the SLINET S 1.0 allows an automated adjustment for slitting.

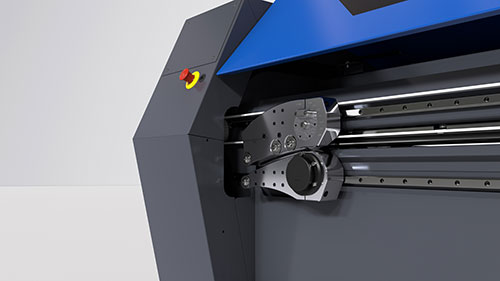

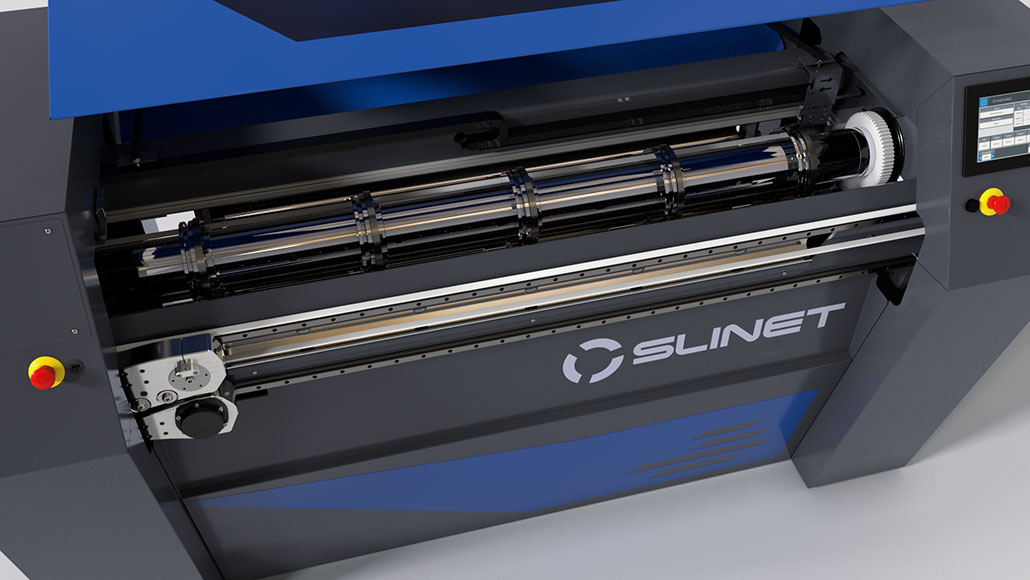

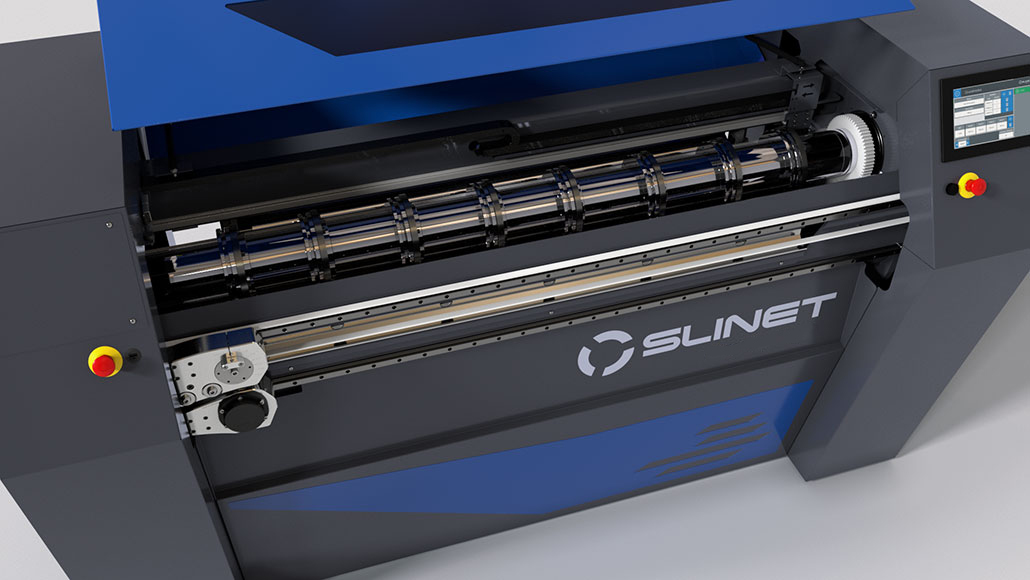

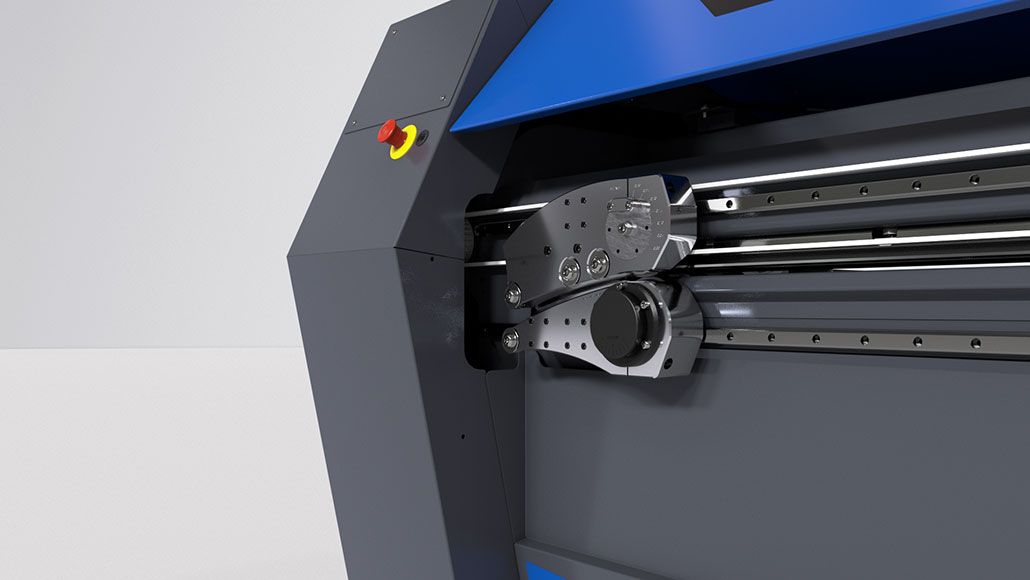

FULL AUTOMATIC KNIFE ADJUSTMENT

Precise positioning using an innovative clamping system. Optionally expandable to up to 8 full automatic positionable knife pairs. No reference cut necessary due to the automatic lifting of the upper knife shaft. No waste of length. Variable cutting gap and overlap adjustment for each material ensures best material-related cutting results.

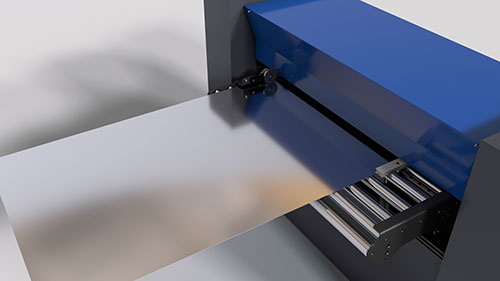

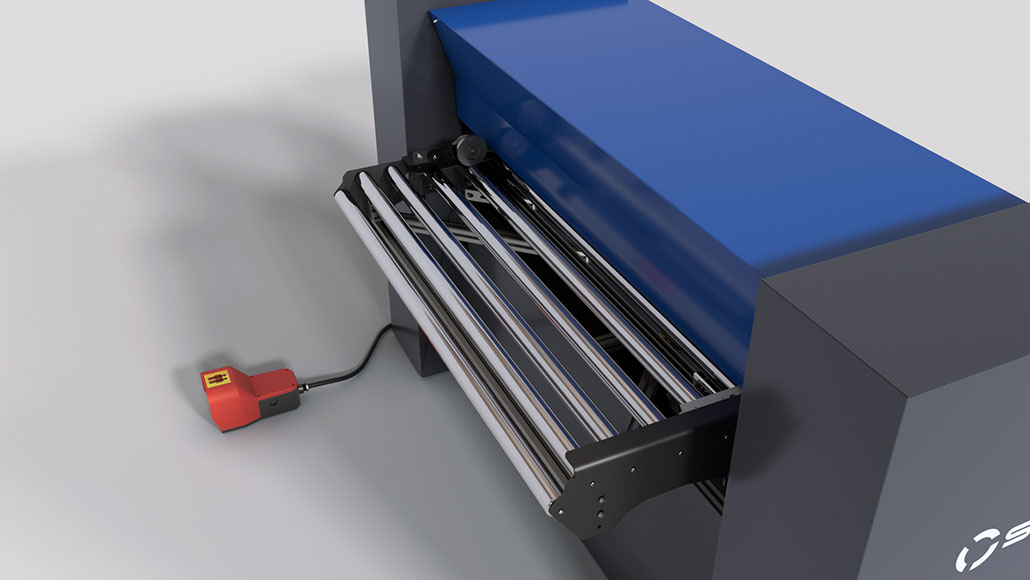

AUTOMATIC SHEET POSITIONING

Position sheet widths from 200 mm to 1250 mm automatically using the foot switch. Variable width alignment including position brake. Extra harden side guide made of special plastic for less abrasion.

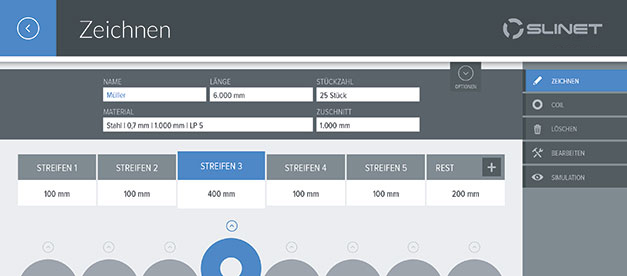

INTUITIVE CONTROL VIA TOUCH PANEL

The standard control impresses with its user-friendliness and clear structure. Easy entry of the automatic slitting knifes. Adding different lengths with different quantities. Can be networked with Variobend long folding machines and double folders as well as other machines and programs. Control side freely selectable.

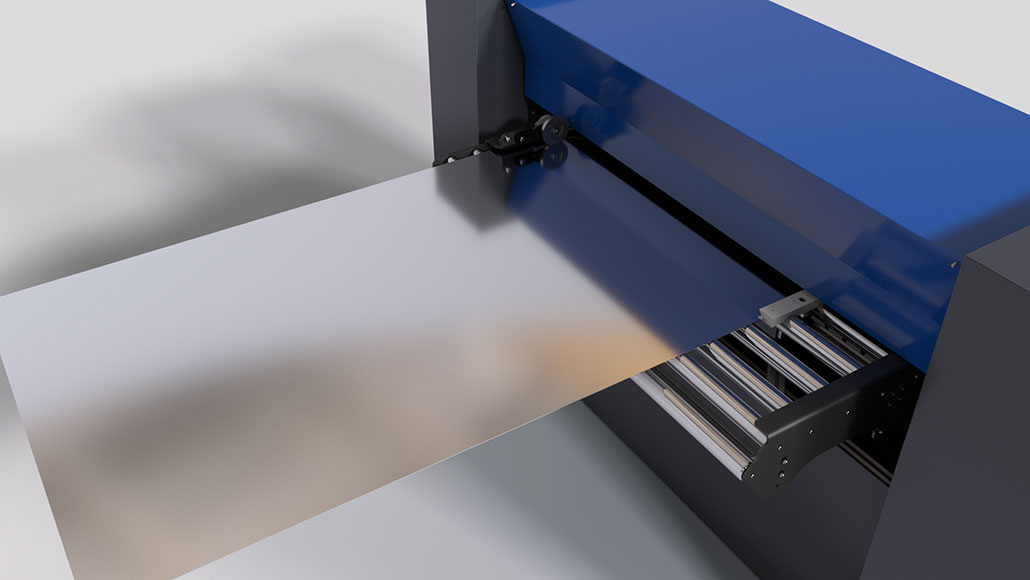

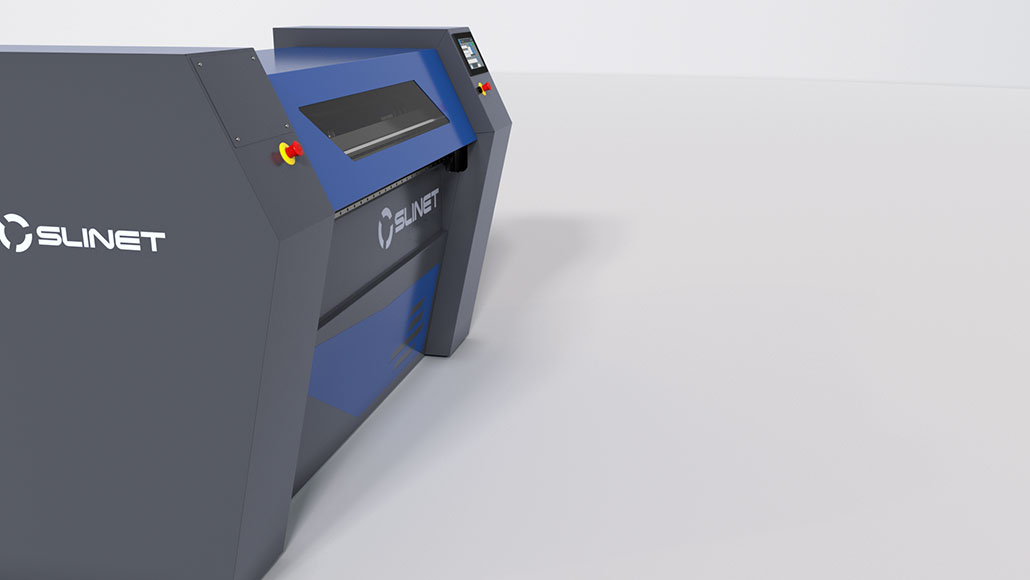

THE CUTTING DEVICE FOR PERFECT CROSS CUTS

The incline position of the cutting blades ensures precise cuts. Variable cutting gap and overlap adjustment for perfect cuts in a wide variety of materials. Rollknifes are grinded on both sides to double the operating time. The belt drive ensures speed, precision and is also maintenance-free. The linear rail technology guarantees a stable, quiet run of the cross cut unit.

COMPACT SIZE

The compact design of the Slinet S 1.0 adapts perfectly to a wide variety of spaces. This means that even companies with limited space can benefit from the new technology. The large number of automations such as the automatic knife adjustment or the automatic side guide also allow further space savings to be achieved.

MASSIVE KNIFE SHAFT

A diameter of 125 mm guarantees perfect cutting results. Because of the big outside diameter the cutting quality will be maximized. In addition, the big outer diameter enables the individual knives to run longer.

Slinet Pro Touch

The SLINET Pro Touch combines efficiency and user-friendliness in an unprecedented relationship. The control which comes in standard stands for its userfriendliness and a clear structure.

Technische Daten

| Maximale Bandbreite | 1250 mm |

| Stahl 400 N/mm² | 1,00 mm |

| Edelstahl 550 N/mm² | 0,80 mm |

| Alu 190 N/mm² | 1,25 mm |

| Blechzuschnitt Mittelstreifen | 65 mm |

| Blechzuschnitt Randstreifen | 15 mm |

| Schnittgenauigkeit | DIN/ISO 2768 (± 0,8 mm/m) |

| Schnittspaltverstellung | 0 – 0,75 mm |

| Längsteilung | 5 Messer (optional 8) |

| Richtmaschine | optional erhältlich mit vier Rollen (automatisch und progressiv) |

| Schnittgeschwindigkeit | 30 m / min |

| Querteilung | Rollenschere |

| Partielles Schneiden | nicht erhältlich |

| Automatisches Coillagersystem | nicht erhältlich |

| Max. Coilgewicht | Abhängig von der Verarbeitungsvariante |

| Etikettendrucker | nicht erhältlich |

| Variobend Pro Touch Steuerung | Inklusive |

| Monitor | 10 Zoll |

| Softwareoptimierer | nicht erhältlich |

| Maschinenvernetzung | Optional erhältlich |

| Foliereinheit | Optional erhältlich |

| Anbindung Recoiler | Optional erhältlich |

- Model S 1.0

-

Slinet S 1.0

The next generation for innovative coil processing.

Markets are subject to permanent change.

In sheet metal forming, this also leads to an ever higher complexity of products and processes. The efficient production of blanks for profiles and flashings requires effective, high flexible and user friendly solutions.

Slinet combines best quality with easy use with highest flexibility and automation.

The cut to length unit SLINET S 1.0 allows precise cuttings with lowest set up time. With its full automated up to 8 knife setting the SLINET S 1.0 allows an automated adjustment for slitting.

FULL AUTOMATIC KNIFE ADJUSTMENT

Precise positioning using an innovative clamping system. Optionally expandable to up to 8 full automatic positionable knife pairs. No reference cut necessary due to the automatic lifting of the upper knife shaft. No waste of length. Variable cutting gap and overlap adjustment for each material ensures best material-related cutting results.

AUTOMATIC SHEET POSITIONING

Position sheet widths from 200 mm to 1250 mm automatically using the foot switch. Variable width alignment including position brake. Extra harden side guide made of special plastic for less abrasion.

INTUITIVE CONTROL VIA TOUCH PANEL

The standard control impresses with its user-friendliness and clear structure. Easy entry of the automatic slitting knifes. Adding different lengths with different quantities. Can be networked with Variobend long folding machines and double folders as well as other machines and programs. Control side freely selectable.

THE CUTTING DEVICE FOR PERFECT CROSS CUTS

The incline position of the cutting blades ensures precise cuts. Variable cutting gap and overlap adjustment for perfect cuts in a wide variety of materials. Rollknifes are grinded on both sides to double the operating time. The belt drive ensures speed, precision and is also maintenance-free. The linear rail technology guarantees a stable, quiet run of the cross cut unit.

COMPACT SIZE

The compact design of the Slinet S 1.0 adapts perfectly to a wide variety of spaces. This means that even companies with limited space can benefit from the new technology. The large number of automations such as the automatic knife adjustment or the automatic side guide also allow further space savings to be achieved.

MASSIVE KNIFE SHAFT

A diameter of 125 mm guarantees perfect cutting results. Because of the big outside diameter the cutting quality will be maximized. In addition, the big outer diameter enables the individual knives to run longer.

- Software

-

Slinet Pro Touch

The SLINET Pro Touch combines efficiency and user-friendliness in an unprecedented relationship. The control which comes in standard stands for its userfriendliness and a clear structure.

- Technische Daten

-

Technische Daten

Maximale Bandbreite 1250 mm Stahl 400 N/mm² 1,00 mm Edelstahl 550 N/mm² 0,80 mm Alu 190 N/mm² 1,25 mm Blechzuschnitt Mittelstreifen 65 mm Blechzuschnitt Randstreifen 15 mm Schnittgenauigkeit DIN/ISO 2768 (± 0,8 mm/m) Schnittspaltverstellung 0 – 0,75 mm Längsteilung 5 Messer (optional 8) Richtmaschine optional erhältlich mit vier Rollen (automatisch und progressiv) Schnittgeschwindigkeit 30 m / min Querteilung Rollenschere Partielles Schneiden nicht erhältlich Automatisches Coillagersystem nicht erhältlich Max. Coilgewicht Abhängig von der Verarbeitungsvariante Etikettendrucker nicht erhältlich Variobend Pro Touch Steuerung Inklusive Monitor 10 Zoll Softwareoptimierer nicht erhältlich Maschinenvernetzung Optional erhältlich Foliereinheit Optional erhältlich Anbindung Recoiler Optional erhältlich - Images

-

- Downloads

Slinet 1.0 vs 1.5

All features at a glance!

See at a glance all the differences between the Slinet 1.0 and the Slinet 1.5 in the comparison table.

Financing

Conceivable turns into feasible!

You are seeking ideal financing – we have financial professionals who know their business. Our financing offers are individually tailored to your situation.

Slinet Service

On the spot quickly

Rely on service which will help you on in the long run. Find out more about the comprehensive service offer of ASCO. From technical after-sales service to financing.